Main Page

The Replimat project is an organized attempt to improve the quality of human life by reducing scarcity.

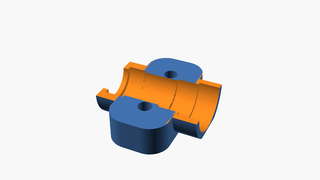

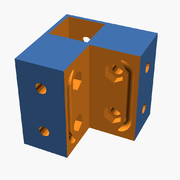

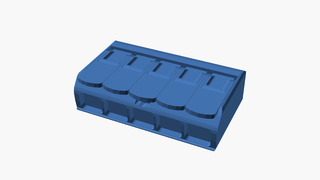

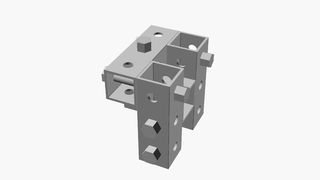

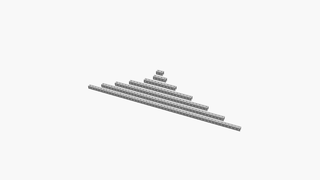

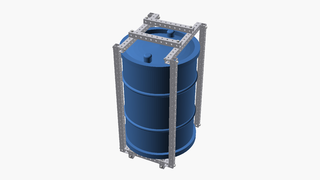

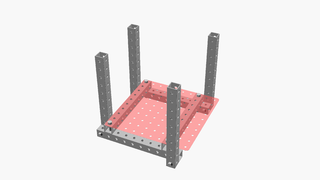

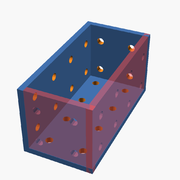

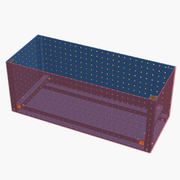

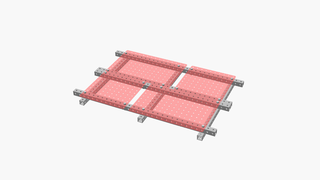

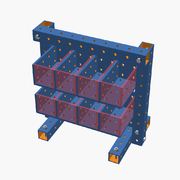

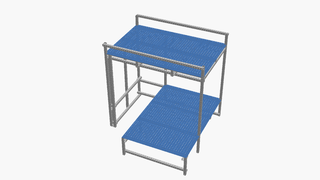

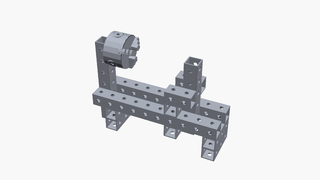

Replimat takes the form of a building system which is broadly interoperable and self-replicating. It is made of a small number of parts reused in many different ways to enable building many things most people need including several of the tools necessary to make more parts from raw materials.

Many parts can simply be cut to form two smaller parts without waste. All Replimat components are designed for disassembly, and cradle-to-cradle reusability and constructed wherever possible from waste or other durable, reusable, renewable, recycled and recyclable materials. Replimat components form a durable, repurposable, mult-use carbon sink for the waste streams of other processes. Component parts which cannot yet be replicated are known as vitamins and development to improve replication of the entire system is hosted in this wiki.

Self reproduction lowers cost, decentralizes production, localizes supply and demand, enables innovation, shortens supply lines, reduces inventory and storage requirements, and encourages the reproduction and spread of knowledge and empowerment.

Replimat is open source hardware, free, libre, and open-source software, and an example of the open design movement. The Replimat project follows a community code of conduct.

Reasons to use Replimat

- Build projects fast while having fun!

- Simple to learn and use

- Designed for disassembly and reuse

- Standard components drastically reduce inventory, manufacturing requirements

- Worldwide availability

- Interoperate with modular construction systems

Design goals

- The right way is the easiest to copy.

- Design parts against the replimat grid to reduce complexity and increase modularity and reusability

- favor parts which can be locally reproduced and have wide application

- enable local production via locally made machines

- consume waste materials for use as raw materials wherever possible - trash to treasure

- promote pools of compatible parts, within which innovation can happen as fast as communication

- strive toward openness and wide application of all components, production processes, firmwares and software

- Avoid unnecessary material transformations. Reduce modifications to standard parts wherever possible.

Parts

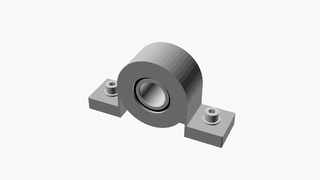

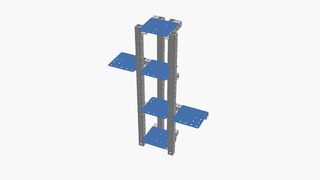

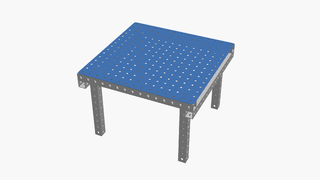

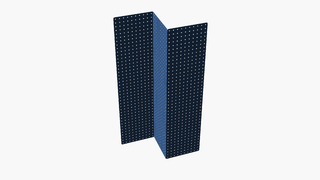

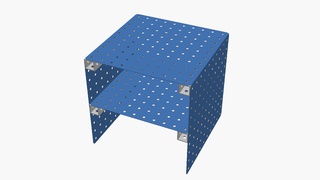

Structures

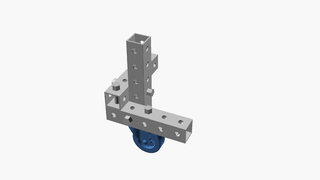

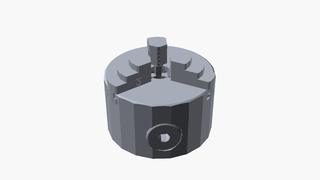

Motions

Springs, Gears and sprockets, Belts, Pulleys

Electrics

Wires, Motors, Magnets, Solar panels, Batteries, Controllers, Speakers, Switches

Fluids

Hoses, Clamps, Couplers, Fluid pumps, Exchangers

Hydraulics

Hydraulic hoses, Hydraulic couplers, Hydraulic pumps, Hydraulic valves, Hydraulic motors, Hydraulic pistons, Hydraulic power units

Pneumatics

Air cylinders, Pneumatic grippers

Heating, ventilation, and air conditioning (HVAC)

Techniques

Fasten loosely until assembled

Trusses

Scissor linkages

Peaucellier-Lipkin linkages

Klann linkages

Jansen linkages

Four bar linkages

Trapezoidal steering

Independent suspensions

Ball and socket joints

Points away from people

Integrated wiring

Bolting

V wheels and angles

Movement: straight line

Movement: live hinges

Movement: rotational

Movement: under no circumstances

Go kart drives

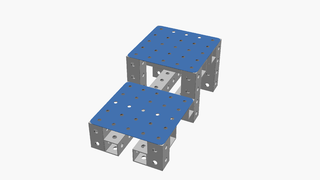

Stacking crates

Techniques to avoid (which sometimes work)

Projects

Tools

Lights

Flashlights

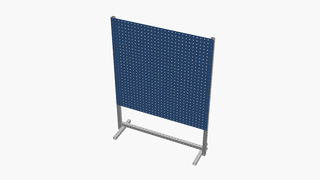

Easels

Soldering irons

Multimeters

Chain saws

Drill bits

Grommet punches

Gear puller

Furniture

Booths

Work lights

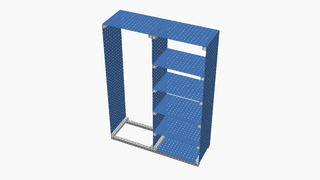

Cubicles

Platforms

Assistive devices

Automation

Energy

Transportation

Cargo cycles

Trucks

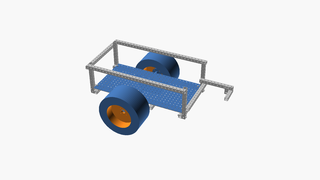

Passenger trailers

Scooters

Boats

Kayaks

Transmissions

Health and safety

Water filters

Face masks

Bathrooms

Ramps

Railings

Shelters

Trailer habitats

Cycle habitats

Geodesic domes

Towers

Information

Home assistants

Cameras

Camera dollies

Projectors

Mesh communicators

Phones

Signs

Heavy equipment

Forklifts

Front loaders

Cranes

Agriculture

Wheelbarrows

Carts

Chicken tractors

Kitchens

Dishwashers

Grow cabinets

Greenhouses

Harvest spinners

Harvest bubblers

Harvest hangers

Tractors

Milking parlors

Pellet presses

Farm robots

Trellises

Fences

Manufacturing

Assembly lines

Conveyor systems

Hangers

Saw stands

Lumber mills

Drill presses

Automated drilling machines

Punch presses

Plasma cutters

Metal mills

CNC routers

Sheet brakes

Copy carvers

Potter's wheels

Kilns

3D printers

Planers (Thicknessers)

Power tools

Plastic recycling centers

Robot arms

Scaffolding

Stands

Table saws

Vacuforming machines

Pallet jacks

Rotary welding positioners

Wire EDM machines

Recycling

Repair

Textiles

Washing Machines

Table looms

Screen printers

Bobbin Winders

Ways to help

- Join the mailing list

- To edit the wiki: register an account

- Upload a photo

- Create a page for your project

- Install the Replimat software.

- Acquire vitamins for the project.

- Become a Patron

- Donate to help fund continued research and development

- Purchase parts from the Replimat store

- Sign up for build days.