Automated drilling machines

| Designers: | Phil Jergenson, RJ Jergenson, Timothy Schmidt, supercool, Mikey, Rongomai, Tobias Grundtvig |

|---|---|

| Tools: | Wrenches |

| Parts: | Frames, Nuts, Bolts, Plates, End caps |

| Techniques: | Shelf joints, Tri joints |

Introduction

Frames can be manufactured by hand, with careful measurement and drilling. While meditative, this work is repetitive and laborious. Time studies of the hand production process using a drill press reveal that positioning the undrilled frame stock for precise drilling consumes the majority of effort. Automating the process in an affordable manner will reduce cost, increase availability, and free time for creative effort.

Challenges

Reducing cost and improving availability of frames requires decentralized manufacturing.

Approaches

A frame drill built from standardized and widely available industrial automation components allows anyone to source the parts they need anywhere to build more frame drills.

Drill guide

Gang drill

Dual gripper drill

This frame drill design makes use of two independently controlled and actuated industrial grippers to move and hold square stock for drilling on all four sides by independently actuated high speed spindles.

Parts

- 2x MHZ2-40D grippers

- 6x HPV6 Linear module ballscrew SFU1204 with Linear Guides HGH15 HIWIN 100% same size with NEMA23 2.8A 56mm stepper motor

Perpendicular axis drill

-

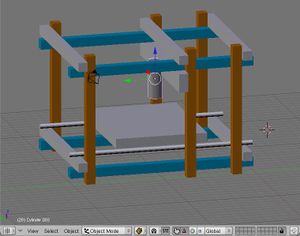

CAD model

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 2x Genmitsu GS-775M Spindle motor

- 4x TN10X50 Industrial air cylinders

- 5 Way, 2 Position pneumatic solenoid valve

- 2x 5mm CNC Spindle Motor ER16 Type A Extension Rod Collect Chuck

- 12x 6mm push fit pneumatic fittings

- 2x Befenybay 100mm linear axes

- BTT E3 Wifi

BeamCNC

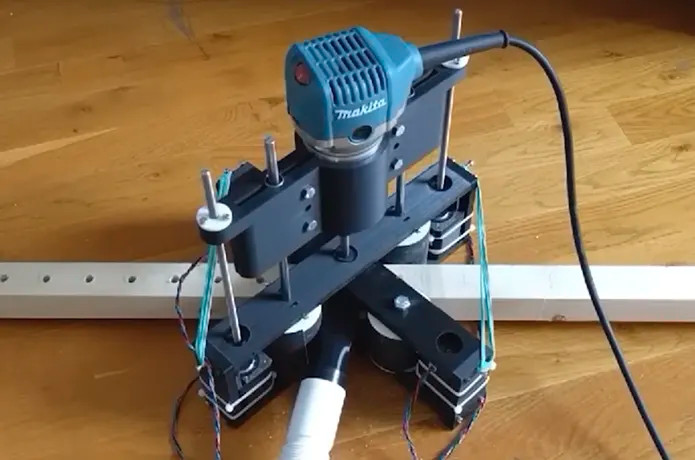

This minimalist design shares many common parts with 3D printers.

Parts

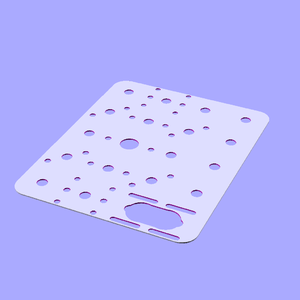

| Part | Quantity | Supplier |

|---|---|---|

|

2 | OpenSCAD File |

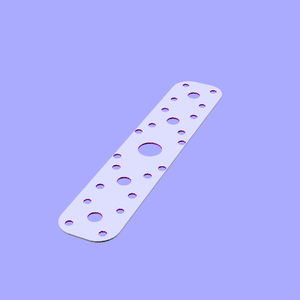

|

1 | OpenSCAD File |

| NEMA-17 stepper motor | 3 | Link |

| roller-raw-material | 12 | CAD File |

| Spindle | 1 | ER16 500W High Speed DC 48V Air Cooling Brushless Spindle Motor + Driver |

| LM8UU Bearing | 1 - pack of 2 | Amazon |

| Drive belt | ||

| Drive pulley | ||

| Controller | ||

| Neoprene foam w/ adhesive backing | Amazon | |

| Drill bit | ||

| Rail Guide Support for 16mm Diameter Shaft | 1 - pack of 4 | Amazon |

| Rail Guide Support for 8mm Diameter Shaft | 1 - pack of 4 | Amazon |

| 350mm 8mm T8 Lead Screw Set Lead Screw+ Copper Nut + Coupler + Pillow Bearing Block | 2 | Amazon |

| Oilite drill bushing | 2 | Mcmaster |

Avid CNC 60120 Pro

Fully automated production development kit

Pneumatic parts

- 8x AOMAG 1/4" DC 24V 2 Way Normally Closed Pneumatic Aluminum Electric Solenoid Air Valve

- 8x https://www.amazon.com/gp/product/B084YTNG2P/ref=ox_sc_act_title_2?smid=A13TRKTV701HHM&psc=1

Tools

Electrical

- extension cords for each tool center

- 10x Heat Shrink Connect Terminals Waterproof solder ring tube terminal insulated bushing wire Butt Connectors protection sleeve $127.70

- 6x Duet3D Duet 3 6HC 3D Printer Controller Board $235ea

- 10x Delta VFD015EL23A VFD-EL Series Drive $260.66

- 4x GRBL Nano High Current Controller Bundle for QueenBee / WorkBee CNC Engraving Milling Machine Desktop DIY Lead CNC Mill $148 $592

- 12x Ender-3S original Meanwell LRS-350-24 power supply for Creality Ender 3 3D printer $37.89 $454.68

- 1x 450nm Professional Continuous 20W/7W/3500mw Laser Cutting / Engraving Module Blue Light With TTL / PWM Modulation for CNC $109ea

Villagekit Grid-bot

A multi-spindle single-axis CNC.

For the framing, we'll use 8040 aluminium extrusion since it's fit for purpose and readily available here in New Zealand.

Where possible, we'll try to use motion control components found in "pro" consumer CNC machines (AvidCNC, RoverCNC, QueenBee, etc), e.g. stepper motors, lead screws, linear rails, etc.