Gears: Difference between revisions

| Line 43: | Line 43: | ||

** mid cost, open source, high performance: [https://bulkman3d.com/product/module-1-0-gear-rack-external/ Module 1.0 Gear Rack – External (0.5 meter)] / [https://bulkman3d.com/product/module-1-0-pinion-gear/ Module 1.0 Pinion Gear] '''16''' / 20 / 32 / '''40''' teeth | ** mid cost, open source, high performance: [https://bulkman3d.com/product/module-1-0-gear-rack-external/ Module 1.0 Gear Rack – External (0.5 meter)] / [https://bulkman3d.com/product/module-1-0-pinion-gear/ Module 1.0 Pinion Gear] '''16''' / 20 / 32 / '''40''' teeth | ||

** proprietary, higher cost, highest performance: [https://www.avidcnc.com/pro-gear-rack-39-1-meter-p-263.html PRO Gear Rack, 39" (1 meter)] / [https://www.avidcnc.com/pro-rack-and-pinion-drive-nema-34-p-226.html PRO Rack and Pinion Drive, NEMA 34] 20 teeth | ** proprietary, higher cost, highest performance: [https://www.avidcnc.com/pro-gear-rack-39-1-meter-p-263.html PRO Gear Rack, 39" (1 meter)] / [https://www.avidcnc.com/pro-rack-and-pinion-drive-nema-34-p-226.html PRO Rack and Pinion Drive, NEMA 34] 20 teeth | ||

* herringbone | |||

=Approaches= | =Approaches= | ||

Revision as of 03:55, 23 October 2021

| Transformations: | 3D Printing, Hobbing, Casting, Injection molding |

|---|---|

| Tools: | 3D printers, Metal lathes, Laser cutters, Plasma cutters, Wire EDM Cutters |

Introduction

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called cogs), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic principle behind the operation of gears is analogous to the basic principle of levers. A gear may also be known informally as a cog. Geared devices can change the speed, torque, and direction of a power source. Gears of different sizes produce a change in torque, creating a mechanical advantage, through their gear ratio, and thus may be considered a simple machine. The rotational speeds, and the torques, of two meshing gears differ in proportion to their diameters. The teeth on the two meshing gears all have the same shape.

Two or more meshing gears, working in a sequence, are called a gear train or a transmission. The gears in a transmission are analogous to the wheels in a crossed, belt pulley system. An advantage of gears is that the teeth of a gear prevent slippage. In transmissions with multiple gear ratios—such as bicycles, motorcycles, and cars—the term "gear" (e.g., "first gear") refers to a gear ratio rather than an actual physical gear. The term describes similar devices, even when the gear ratio is continuous rather than discrete, or when the device does not actually contain gears, as in a continuously variable transmission.

Furthermore, a gear can mesh with a linear toothed part, called a rack, producing translation instead of rotation.

Challenges

We need gear families that all work with each other. This includes popular construction toys. But we're also scaling stuff up to work with Big Iron, like 40mm and 100mm frames. And rack and pinion.

- Meccano/Erector/Vex

- LEGO Technic

- spur gears: 8, 16, 24, 40, gear expert 9, gear expert 15, gear expert 21

- bevel gears: 12, 20, 28, 36

- crown gears: 24, 28

- Bicycle

- rack

- low cost, open source, good performance: Internal Insert Module 1.0 Gear Rack (0.5 meter) / Module 1.0 Pinion Gear 16 / 20 / 32 / 40 teeth

- mid cost, open source, high performance: Module 1.0 Gear Rack – External (0.5 meter) / Module 1.0 Pinion Gear 16 / 20 / 32 / 40 teeth

- proprietary, higher cost, highest performance: PRO Gear Rack, 39" (1 meter) / PRO Rack and Pinion Drive, NEMA 34 20 teeth

- herringbone

Approaches

Laser Cutter

- Fabrication on laser cutters is common, works well.

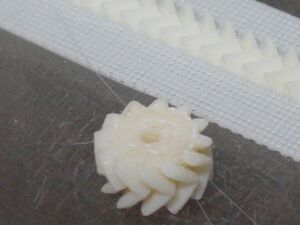

3D Printing

CNC mill/router

- Sherline examples

- Taig Mill examples

- Bridgeport examples

Hybrid

Hybrid fabrication; RepRapping and then precise tidying of each layer with a milling/routing head is the most promising.

- Direct: We can make the plastic gear directly

- Mold: We can make the molds for filled epoxy gears. See HandmadeGears.

Hobbing

- Timothy Edward's build of a Meccano Gear Making Machine, technically a gear hobber:

via http://edwards.web.users.btopenworld.com/meccano/modelgear.htm

Wire EDM

- Forrest Higgs proposed this once.

Casting/Mouldmaking

- We can make molds for Filled epoxy

CNC plasma cutting

2D cuts can be stacked, with through holes for bolts to provide alignment and compression, allowing for the construction of sturdy power transmission components for keyed shafts.