Automated drilling machines: Difference between revisions

No edit summary |

No edit summary |

||

| Line 54: | Line 54: | ||

Drill guide 1.jpg | Drill guide 1.jpg | ||

Drill guide 2.jpg | Drill guide 2.jpg | ||

Drill guide 6.jpg | |||

</gallery> | </gallery> | ||

Revision as of 12:28, 22 January 2021

Challenges

Frames can be manufactured by hand, with careful measurement and drilling. While meditative, this work is repetitive and laborious. Time studies of the hand production process using a drill press reveal that positioning the undrilled frame stock for precise drilling consumes the majority of effort. Automating the process in an affordable manner will reduce cost, increase availability, and free time for creative effort.

Approaches

Flat pack frame drill

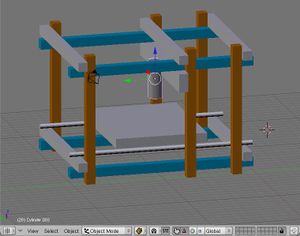

The frame drill automatically drills regularly spaced holes in square raw material to produce reusable Replimat frames. It is constructed of a number of custom plates, motors, a controller, and several 3D printed parts.

Tools

Parts

| Part | Quantity | Supplier |

|---|---|---|

| plate-drill-machine | 2 | OpenSCAD File |

| plate-drill-machine-spindle | 1 | OpenSCAD File |

| NEMA-17 stepper motor | 3 | Link |

| roller-raw-material | 12 | CAD File |

| Spindle | 1 | ER16 500W High Speed DC 48V Air Cooling Brushless Spindle Motor + Driver |

| LM8UU Bearing | 1 - pack of 2 | Amazon |

| Drive belt | ||

| Drive pulley | ||

| Controller | ||

| Neoprene foam w/ adhesive backing | Amazon | |

| Drill bit | ||

| Rail Guide Support for 16mm Diameter Shaft | 1 - pack of 4 | Amazon |

| Rail Guide Support for 8mm Diameter Shaft | 1 - pack of 4 | Amazon |

| 350mm 8mm T8 Lead Screw Set Lead Screw+ Copper Nut + Coupler + Pillow Bearing Block | 2 | Amazon |

| Oilite drill bushing | 2 | Mcmaster |

Drill guide

Gang drill

Dual gripper frame drill

Challenges

Reducing cost and improving availability of replimat frames requires decentralized manufacturing.

Approaches

A frame drill built from standardized and widely available industrial automation components allows anyone to source the parts they need anywhere to build more frame drills.

This frame drill design makes use of two independently controlled and actuated industrial grippers to move and hold square stock for drilling on all four sides by independently actuated high speed spindles.

Parts

- 2x MHZ2-40D grippers

- 2x Befenybay 100mm linear axes

- 4x Genmitsu GS-775M Spindle motor

- 4x 2060U 775 Motor mount and linear axis

- 2x or 4x TN10X50 Industrial air cylinders

- 5 Way, 2 Position pneumatic solenoid valve

- 4x 5mm CNC Spindle Motor ER16 Type A Extension Rod Collect Chuck

- 12x 6mm push fit pneumatic fittings