Automated drilling machines: Difference between revisions

From

No edit summary |

|||

| Line 2: | Line 2: | ||

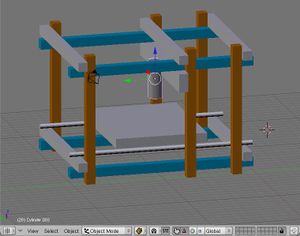

[[Image:Eiffel_Concept.jpg|thumb|right|Early version of RepRap Eiffel, showing the grid beam TriLap joints. (The beams should have through-holes repeating along the side.)]] | [[Image:Eiffel_Concept.jpg|thumb|right|Early version of RepRap Eiffel, showing the grid beam TriLap joints. (The beams should have through-holes repeating along the side.)]] | ||

= | =Challenge= | ||

[[Frames]] can be manufactured by hand, with careful measurement and drilling. While meditative, this work is repetitive and laborious. Automating the process in an affordable manner will reduce cost, increase availability, and free time for creative effort. | [[Frames]] can be manufactured by hand, with careful measurement and drilling. While meditative, this work is repetitive and laborious. Automating the process in an affordable manner will reduce cost, increase availability, and free time for creative effort. | ||

=Approach= | |||

The frame drill automatically drills regularly spaced holes in [[square raw material]] to produce reusable Replimat [[frames]]. It is constructed of a number of custom [[plates]], [[motors]], a [[controller]], and several 3D printed parts. | The frame drill automatically drills regularly spaced holes in [[square raw material]] to produce reusable Replimat [[frames]]. It is constructed of a number of custom [[plates]], [[motors]], a [[controller]], and several 3D printed parts. | ||

== Bill of Materials == | |||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

| Line 48: | Line 48: | ||

|} | |} | ||

=To do= | |||

* upload CAD | * upload CAD | ||

* rev with Marc | * rev with Marc | ||

* quote with Andy | * quote with Andy | ||

=History= | |||

https://wiki.replimat.org/wiki/Eiffel | https://wiki.replimat.org/wiki/Eiffel | ||

Revision as of 21:53, 1 July 2020

Challenge

Frames can be manufactured by hand, with careful measurement and drilling. While meditative, this work is repetitive and laborious. Automating the process in an affordable manner will reduce cost, increase availability, and free time for creative effort.

Approach

The frame drill automatically drills regularly spaced holes in square raw material to produce reusable Replimat frames. It is constructed of a number of custom plates, motors, a controller, and several 3D printed parts.

Bill of Materials

| Part | Quantity | Supplier |

|---|---|---|

| plate-drill-machine | 2 | CAD File |

| plate-drill-machine-spindle | 1 | CAD File |

| NEMA-17 stepper motor | 3 | Link |

| roller-raw-material | 12 | CAD File |

| Spindle | 1 | ebay |

| LM8UU Bearing | 1 - pack of 2 | Amazon |

| Acme threaded rod, coupler, nut, pillow block bearings | ||

| Roller | ||

| Drive belt | ||

| Drive pulley | ||

| Controller | ||

| Neoprene foam w/ adhesive backing | Amazon | |

| Drill bit | ||

| Rail Guide Support for 16mm Diameter Shaft | 1 - pack of 4 | Amazon |

| Rail Guide Support for 8mm Diameter Shaft | 1 - pack of 4 | Amazon |

| 350mm 8mm T8 Lead Screw Set Lead Screw+ Copper Nut + Coupler + Pillow Bearing Block | 2 | Amazon |

| Oilite drill bushing | 2 | Mcmaster |

To do

- upload CAD

- rev with Marc

- quote with Andy