Wheelchairs: Difference between revisions

No edit summary |

No edit summary |

||

| Line 45: | Line 45: | ||

=Approaches= | =Approaches= | ||

Based on our project needs, we created the following project specifications: | Based on our project needs, we created the following project specifications: | ||

| Line 66: | Line 58: | ||

** Turn radius < 44" (taken from ADA chair dimensions) | ** Turn radius < 44" (taken from ADA chair dimensions) | ||

<gallery> | |||

FQC7ENOIW5JB2UM.jpg| | |||

F90BKRYIW5JB2UO.jpg| | |||

FQM2AA7IW5JB2UR.jpg| | |||

FE28HTLIW5JB2V0.jpg| | |||

FI0UJE2IW5JB2VF.jpg| | |||

</gallery> | |||

As stated previously, we wanted our materials to be readily available and easily accessible for anyone to find. The reasoning behind this was to avoid long downtimes or having to go through a supplier that has a monopoly on selling specific parts (i.e. only one set of motors that works and only one supplier who offers them). This would also allow someone with a chair in need of repair to go to their local hardware store or order a part online and replace the faulty one quickly on the chair themselves or with a little help. Thus long down times would ideally be eliminated. | As stated previously, we wanted our materials to be readily available and easily accessible for anyone to find. The reasoning behind this was to avoid long downtimes or having to go through a supplier that has a monopoly on selling specific parts (i.e. only one set of motors that works and only one supplier who offers them). This would also allow someone with a chair in need of repair to go to their local hardware store or order a part online and replace the faulty one quickly on the chair themselves or with a little help. Thus long down times would ideally be eliminated. | ||

Revision as of 12:39, 3 October 2021

| Designers: | jtaggard |

|---|---|

| Tools: | Wrenches, Soldering irons |

| Parts: | Frames, Nuts, Bolts, Motors, Batteries, Wires, Electrical connectors, Wheels |

| Techniques: | Wheels and axles, Tri joints |

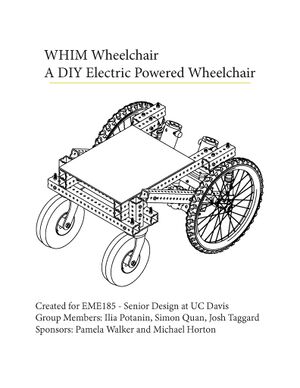

Introduction

A wheelchair is a chair with wheels, used when walking is difficult or impossible due to illness, injury, problems related to old age, or disability.

Challenges

Current electric wheelchair users constantly have to deal with high insurance prices and long wait times when it comes to purchasing and repairing their electric wheelchair. Specifically, our sponsor Pamela had to wait several months just to have her caster wheel assembly replaced. For someone who requires their chair for a main mode of transport, this is unacceptable. Additionally, the wheelchair manufacturers have been creating chairs with lower specs (torque, average speed, etc.) while insurance companies are raising the costs to own such a chair.

The goal of the project was to avoid these negative setbacks and also prove someone could build their own electric powered wheelchair in their garage using basic tools such as a chop saw and drill press. The scope of our project included producing a working drive-train and frame that would provide a solid foundation for our sponsors, WHIM Unlimited, to develop a fully working and refined electric powered wheelchair. We hope this assembly guide will provide the necessary framework for others to build their own chair, ending the longtime dependence on inconvenient health and insurance companies. This guide is by no means includes a final product, but rather a proof of concept and a framework for others to build off of to fit their own personal mobility needs.

Based on our meetings with our sponsors, we determined our chair would need to exhibit the following:

- Powertrain

- Powerful motor

- Ability to climb road curbs

- Good acceleration

- Body

- Stable and sturdy

- Maneuverable

- Meets ADA specifications

- Overall

- Safe

- Modular

- Easy to build (no complex geometries)

- Easily obtainable standard parts (minimize custom parts)

- Long lasting

- Adaptable to the user

Approaches

Based on our project needs, we created the following project specifications:

- Powertrain Specifications

- 3 MPH up a 4 degree incline

- Can go up a 10 degree curb (bump)

- Accelerate from 0 to 5 MPH in under 2 seconds

- Max speed of 8 MPH (wheelchairs on the market average about 4 MPH)

- Frame Specifications

- Max size of 30"x42" (ADA)

- Chair height of 15" to 25" off the ground

- Can handle a 500 lb load

- Turn radius < 44" (taken from ADA chair dimensions)

As stated previously, we wanted our materials to be readily available and easily accessible for anyone to find. The reasoning behind this was to avoid long downtimes or having to go through a supplier that has a monopoly on selling specific parts (i.e. only one set of motors that works and only one supplier who offers them). This would also allow someone with a chair in need of repair to go to their local hardware store or order a part online and replace the faulty one quickly on the chair themselves or with a little help. Thus long down times would ideally be eliminated.

As part of our project, we researched different suppliers to find our initial sources for the parts, but we also found alternate suppliers and parts in case the primary source disappeared. The overall cost of the chair was roughly $2000 as compared to chairs on the market that range from $1000 to $6000+. Our chair is on the lower end of this price range, but it offers the specifications one would find on a more expensive model. Overall, our cost could be reduced with various design improvements and material changes, but again this was meant to serve as an initial prototype and proof of concept.

- tools Needed, Custom Parts, and Gridbeam Cut List

As Mechanically Engineering students, we had access to a full machine shop capable of creating all the custom parts to our hearts content. Unfortunately, the average person doesn't have this luxury, thus if we took advantage of these tools then it could get quite difficult for someone to follow our instructions. For this reason, we chose to work with tools that the average person may have laying around in their garage.

A majority of our build was made using only a chop saw and drill press, however we did have to make a few custom parts. These included the driveshaft, motor mounts, and driveshaft coupler parts. We felt these parts required the most stability and reliability possible, so we chose to make simplified custom parts. We then created drawings for these parts so someone could go to a local machine shop or makerspace or even contact an online service to have them made.

We were able to use only a few custom parts thanks to our choice of framing material: Gridbeam. This material is best described as 2" square tubing with 7/16" mounting holes every 1". Unfortunately, the material is fairly heavy (~5 lbs/foot) but it does make assembly fairly easy once the cuts have been made.

- Step 4: Caster Assembly

During the summer before my Senior year, I had the privilege to work at Aerojet Rocketdyne as Visual Planning Intern. Long story short, we would take advanced rocket assemblies and create a virtual build of the model so the technicians on the floors had something easy to follow when assembling the parts. Basically, I created Ikea/Lego-like instructions for rockets. Seeing as the wheelchair needed a set of easy to follow plans, I created a guide by applying the same skills I used during my internship. The finished result is a clean, easy to follow list of steps that doesn't require a B.S. in Mechanical Engineering to follow.

We created our entire assembly using Solidworks. I then planned out the best way to assemble the parts, and create the virtual build by putting together vector drawings using Adobe Illustrator and InDesign. The first assembly we decided to build is the caster assembly. The caster wheels make it a little awkward since they rolled around fairly easily, so it's best to have some help or somewhere to put the assembly as it comes together. Make sure all the Gridbeam pieces are square to each other before tightening the bolts.

- Step 5: Motor Assembly

The next assembly to put together is the motor assembly. This one is a little trickier to put together and required some finessing in order to get the motors, driveshaft and motor mounts to all line up. Luckily none of the fasteners are permanent so if you mess up there's nothing to be worried about.

- Step 6: Final Assembly

Once the caster and motor assemblies are together it's time to put it all together. Both assemblies are fairly heavy and awkward in size so it helps to have at least two people to put them together.

- Step 7: Controlling the Chair

Our chair utilizes the open sourced Arduino and two H-Bridge shields to control the electricity to each motor. We also use a USB host shield and a cheap USB joystick to provide an intuitive control scheme. For batteries, we used two 12V lead acid batteries hooked up in series to provide a total voltage of 24V. We found this to be more than enough power and control for the prototype, however the Aruidno code needed to be refined further before the chair could be used for everyday use.

Note: I mainly worked on the overall chair design and documenting how we assembled the build. One of my other teammates worked on the actual Arduino code, but I believe he just researched code that other people had used with the H-Bridge shields. Again, we were Mechanical Engineers so learning/writing code from the ground up wasn't really really in our scope. Apologies if the lack of refined controller code is what prevents you from making your own chair.

- Step 8: Testing the Chair

As part of our project, we needed to prove our chair met the specifications we outlined at the beginning of our project. We also participated in a Senior Design Showcase put on by our school where all our classmates also showed off what they had worked on for two quarters. Everyone at the showcase was impressed with the maneuverability and ruggedness of our chair and we didn't shy away from showing it off. Attached are some videos of our initial benchmark tests along with footage from our showcase. By the end of our project, we were happy to have something that actually worked and had a fun time showing it off and playing with it.

- Step 9: Design Recommendations, Add-ons and Accessories

Seeing as our course was only two quarters and we had a finite budget, we didn't get to fully develop the chair like we would have. It's obviously missing a chair and other elements to provide a smooth and comfortable ride. We iterated through our design countless times but there's always room for improvement. Again, this is mainly a proof of concept and initial crack at a problem, so there are many things that could improve the chair.

- Step 10: Maintenance Guide

No machine works well just by itself, but instead requires maintenance to prolong it's life. Our wheelchair is no exception. Although we were done with the project a few weeks after it was built, we still were able to forecast which components would require upkeep in order to have the best performance possible. These suggestions are mainly based on the manufacturer's suggestions for the parts, and we don't know for sure if problems would arise with other parts.

- Step 11: Assembly Document

Overall, this project was my first time applying my coursework to an actual, real world problem. I hope if you choose to follow this Instructable that you share with me your hardships or any suggestions for improvements you may have. At the start of this project, we wanted to make the chair easy for anyone to follow, but at the same time allow others to adapt it to their own needs. Thank you for taking the time to read through my Instructable, and I hope you enjoyed it as much as I did making it and the DIY Electric Wheelchair contained herein.

File:Assembly-instructions.pdf