Three point hitches: Difference between revisions

No edit summary |

|||

| Line 16: | Line 16: | ||

=Challenges= | =Challenges= | ||

Build hitches to meet industry standard sizes using [[:Category:Parts|parts]] and as few [[vitamins]] as possible. | |||

==Size categories== | ==Size categories== | ||

There are five different hitch sizes, called categories. The higher category hitches have sturdier lift arms and larger connector pins. | There are five different hitch sizes, called categories. The higher category hitches have sturdier lift arms and larger connector pins. | ||

Revision as of 01:26, 22 May 2021

| Parts: | Frames, Nuts, Bolts, End caps, Plates |

|---|---|

| Techniques: | Tri joints, Space frames, Trusses, Bolting |

Introduction

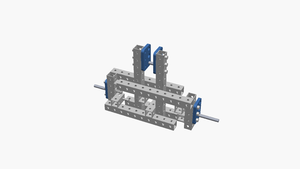

The three-point hitch is a widely used type of hitch for attaching ploughs and other implements to an agricultural or industrial tractor. The three points resemble either a triangle, or the letter A. Three-point attachment is the simplest and the only statically determinate way of joining two bodies in engineering.

Challenges

Build hitches to meet industry standard sizes using parts and as few vitamins as possible.

Size categories

There are five different hitch sizes, called categories. The higher category hitches have sturdier lift arms and larger connector pins.

| Category | Tractor power | Top link pin diameter* | Lift arm pin diameter | Lower hitch spacing |

|---|---|---|---|---|

| 0 | Up to 20hp | 5/8 in | 5/8 in | 20 in |

| 1 | 20 to 45hp | 3/4 in | 7/8 in | 28 in |

| 2 | 40 to 100hp | 1 in | 1+1/8 in | 34 in |

| 3 | 80 to 225hp | 1+1/4 in | 1+7/16 in | 40 in |

| 4 | More than 180hp | 1+3/4 in | 2 in | 48 in |

There are also variants to the above categories denoted by N, (narrow). These utilize the pin sizes of the listed category, but the width of a category one step lower. The N variations are common in "quick hitches" and allow larger tractors to easily hook onto smaller utility implements.

- * refers to implement end; tractor end not specified

Approaches

-

Plate adapts to 5/8 inch, 3/4 inch, 7/8 inch pins for category 0 and 1

-

Category 0 hitch