Motors

Challenges

Electric motors are expensive and difficult to manufacture, and not universally available. Most thermoplastics operate at low melting points not suitable for intense or prolonged motor operation.

Approaches

3D print an electric motor using recycled plastics selected specially for high durability and heat resistance, 3D printers, and vitamins. Design with investment casting, and direct metal printing in mind.

Stepper Motors

Dual-shaft NEMA-17 Stepper motor File:Stepper-motor-basics.pdf

References

Servo Motors

- Rotary encoder

- Mechaduino servo controller

Utility Motors

Christoph Laimer's Youtube channel

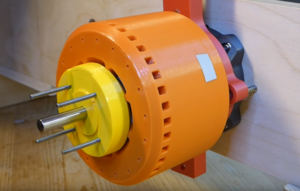

Step by step instructions for making the 600W, 3d-printed Halbach array brushless motor.

3d-printed Halbach Motor - Update, Tuning, Testing (and sending it to FliteTest)

3d-printed brushless Motor - Explore max. RPM (make it explode)

3D Printed Motor on an Ultralight!

Alternatives

- 1/2 Horsepower 115 Volt AC 1725 RPM Magnetek Motor

- Salvaged AC, DC, or universal motor - permanent magnet or inductive

Sterling motor

Tools

Development targets

- https://www.thingiverse.com/thing:20177

- https://www.thingiverse.com/thing:11164

- https://www.thingiverse.com/thing:251004

- IRFP260N mosfets - 50A 200V - $3 ea Ebay - same as Controller