Metal lathes: Difference between revisions

From

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

{{Projects infobox | {{Projects infobox | ||

|image = Lathe.scad.png | |image = Lathe.scad.png | ||

| | |designers = [[User:Tim|Timothy Schmidt]] | ||

|date = 2013 | |date = 2013 | ||

|vitamins = | |vitamins = | ||

| Line 10: | Line 10: | ||

|parts = [[Frames]], [[Nuts]], [[Bolts]], [[End caps]], [[Plates]], [[Chucks and collets]] | |parts = [[Frames]], [[Nuts]], [[Bolts]], [[End caps]], [[Plates]], [[Chucks and collets]] | ||

|techniques = [[Tri joints]], [[Shelf joints]], [[Clamping brackets]] | |techniques = [[Tri joints]], [[Shelf joints]], [[Clamping brackets]] | ||

|git = | |||

|stl = | |||

}} | }} | ||

Revision as of 17:36, 18 September 2021

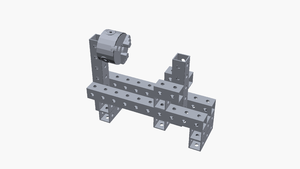

Project: Metal lathes

| Designers: | Timothy Schmidt |

|---|---|

| Tools: | Wrenches |

| Parts: | Frames, Nuts, Bolts, End caps, Plates, Chucks and collets |

| Techniques: | Tri joints, Shelf joints, Clamping brackets |

Introduction

A lathe (/leɪð/) is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

Challenges

Approaches

9x20 Class Lathes

Development targets

CNC lathes which are not fitted with a bar feed mechanism can equip a tool location with a bar puller like these or any of a number of other designs, to increase automation of part production.

- tool changer

- live tooling attachment

- Tailstock