Metal lathes: Difference between revisions

From

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

{{Projects infobox | {{Projects infobox | ||

|image | |image = Lathe.scad.png | ||

|designer | |designer = [[User:Tim|Timothy Schmidt]] | ||

|date | |date = 2013 | ||

|vitamins = | |vitamins = | ||

|materials = | |materials = | ||

|transformations = | |transformations = | ||

|lifecycles = | |lifecycles = | ||

|tools | |tools = [[Wrenches]] | ||

|parts | |parts = [[Frames]], [[Nuts]], [[Bolts]], [[End caps]], [[Plates]], [[Chucks and collets]] | ||

|techniques | |techniques = [[Tri joints]], [[Shelf joints]] | ||

}} | }} | ||

| Line 29: | Line 29: | ||

* live tooling attachment | * live tooling attachment | ||

* [https://www.amazon.com/dp/B07DGSFKGV/ Tailstock] | * [https://www.amazon.com/dp/B07DGSFKGV/ Tailstock] | ||

=References= | =References= | ||

Revision as of 12:22, 26 May 2021

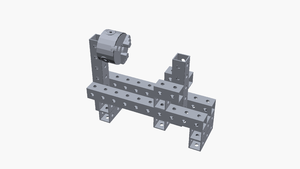

Project: Metal lathes

| Tools: | Wrenches |

|---|---|

| Parts: | Frames, Nuts, Bolts, End caps, Plates, Chucks and collets |

| Techniques: | Tri joints, Shelf joints |

Introduction

Challenges

Approaches

9x20 Class Lathes

Development targets

CNC lathes which are not fitted with a bar feed mechanism can equip a tool location with a bar puller like these or any of a number of other designs, to increase automation of part production.

- tool changer

- live tooling attachment

- Tailstock