Metal lathes: Difference between revisions

From

No edit summary |

No edit summary |

||

| Line 4: | Line 4: | ||

|date = 2013 | |date = 2013 | ||

|tools = [[Wrenches]] | |tools = [[Wrenches]] | ||

|parts = [[Frames]], [[Nuts]], [[Bolts]], [[End caps]], [[Plates]] | |parts = [[Frames]], [[Nuts]], [[Bolts]], [[End caps]], [[Plates]], [[Chucks and collets]] | ||

|techniques = [[Tri joints]], [[Shelf joints]] | |techniques = [[Tri joints]], [[Shelf joints]] | ||

}} | }} | ||

| Line 26: | Line 26: | ||

* [https://www.thingiverse.com/thing:5791 Four Jaw Self Centring Chuck] | * [https://www.thingiverse.com/thing:5791 Four Jaw Self Centring Chuck] | ||

* [https://www.instructables.com/3D-Printed-Lathe/ 3D printed lathe] | * [https://www.instructables.com/3D-Printed-Lathe/ 3D printed lathe] | ||

* [https://www.aliexpress.com/item/32759631702.html CNC 4th Axis 3 Jaw 100mm Lathe Chuck K11-100 Hollow Shaft CNC Rotary Axis + Tailstock-5 Ratio 6:1 Hollow Shaft for CNC Router] | |||

Revision as of 07:35, 13 April 2021

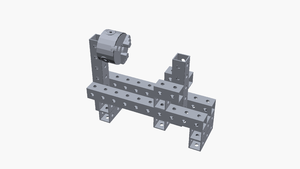

Project: Metal lathes

| Tools: | Wrenches |

|---|---|

| Parts: | Frames, Nuts, Bolts, End caps, Plates, Chucks and collets |

| Techniques: | Tri joints, Shelf joints |

Challenges

Approaches

Development targets

CNC lathes which are not fitted with a bar feed mechanism can equip a tool location with a bar puller like these or any of a number of other designs, to increase automation of part production.

- tool changer

- live tooling attachment

- Tailstock