3D printers: Difference between revisions

From

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

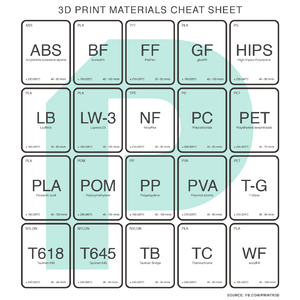

[[File:Filaments.png|thumb]] | [[File:Filaments.png|thumb]] | ||

= | =Challenges= | ||

Subtractive manufacturing can produce many goods - particularly with multi-step production processes and multiple parts. But some objects simply can't be made via those means. Others are simpler and faster to manufacture in a single operation additively. | Subtractive manufacturing can produce many goods - particularly with multi-step production processes and multiple parts. But some objects simply can't be made via those means. Others are simpler and faster to manufacture in a single operation additively. | ||

= | =Approaches= | ||

Use [https://wiki.replimat.org/wiki/Bearings#Linear_Bearings linear bearings], [[motors]], and a [[controller]] to build a 3D printer. A hotend designed to consume plastic pellets instead of filament allows for direct recycling of shredded plastic goods. | Use [https://wiki.replimat.org/wiki/Bearings#Linear_Bearings linear bearings], [[motors]], and a [[controller]] to build a 3D printer. A hotend designed to consume plastic pellets instead of filament allows for direct recycling of shredded plastic goods. | ||

Revision as of 07:11, 17 July 2020

Challenges

Subtractive manufacturing can produce many goods - particularly with multi-step production processes and multiple parts. But some objects simply can't be made via those means. Others are simpler and faster to manufacture in a single operation additively.

Approaches

Use linear bearings, motors, and a controller to build a 3D printer. A hotend designed to consume plastic pellets instead of filament allows for direct recycling of shredded plastic goods.

Tools

Parts

| Quantity | Part | Link |

|---|---|---|

| 1 | Mahor pellet hot end | mahor.xyz |