Planers: Difference between revisions

From

No edit summary |

No edit summary |

||

| Line 10: | Line 10: | ||

|parts = [[Frames]], [[Nuts]], [[Bolts]], [[Plates]], [[End caps]] | |parts = [[Frames]], [[Nuts]], [[Bolts]], [[Plates]], [[End caps]] | ||

|techniques = [[Shelf joints]], [[Tri joints]] | |techniques = [[Shelf joints]], [[Tri joints]] | ||

| | |files = | ||

|suppliers = | |||

|git = | |git = | ||

}} | }} | ||

Revision as of 08:58, 23 September 2021

Project: Planers

| Designers: | Timothy Schmidt |

|---|---|

| Tools: | Wrenches |

| Parts: | Frames, Nuts, Bolts, Plates, End caps |

| Techniques: | Shelf joints, Tri joints |

Introduction

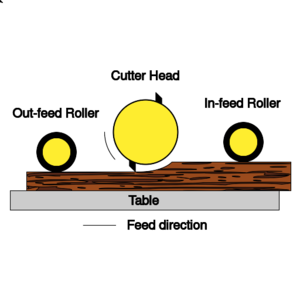

A thickness planer (also known in the UK and Australia as a thicknesser or in North America as a planer) is a woodworking machine to trim boards to a consistent thickness throughout their length and flat on both surfaces.

Challenges

Planers or thicknessers use a spinning blade or series of cutting tools to flatten a board to a desired thickness. Thicknessing wood can require a powerful motor and sharp tools moving quickly. Engineering a safer tool than commercial equivalents is a goal, but great care with respect to safety should be practiced around any such tool.

Approaches

Parts

- Dewalt portable planer

- Shelix helical carbide cutting head - shares tooling with lathe and mill

Interoperability

Development targets

- Replimat planer (frame, pillow block bearings, flat steel blades sharpened on grinder with replimat linear bearing attachment, motor, V wheels, sheet stock, hardware)