Frames: Difference between revisions

No edit summary |

|||

| Line 102: | Line 102: | ||

* 8 mm threaded steel rod (aka "[[threaded rod]]" or "allthread" or "M8 studding"): Many RepRaps and RepStraps use all-thread as a easily-adjustable frame material. Many also have at least one axis driven by a "lead screw" of 8 mm threaded road or nearly equivalent 5/16" threaded rod that acts as a worm gear, turned by a [[stepper motor]], that pushes parts back and forth. A few use bigger sizes such as M12 and M10 threated rods in the [[BiBONE]][http://forums.reprap.org/read.php?152,128970] or smaller sizes such as the 1/4 inch threaded rod used in smaller [[SAE Mendel]] machines. | * 8 mm threaded steel rod (aka "[[threaded rod]]" or "allthread" or "M8 studding"): Many RepRaps and RepStraps use all-thread as a easily-adjustable frame material. Many also have at least one axis driven by a "lead screw" of 8 mm threaded road or nearly equivalent 5/16" threaded rod that acts as a worm gear, turned by a [[stepper motor]], that pushes parts back and forth. A few use bigger sizes such as M12 and M10 threated rods in the [[BiBONE]][http://forums.reprap.org/read.php?152,128970] or smaller sizes such as the 1/4 inch threaded rod used in smaller [[SAE Mendel]] machines. | ||

* 8 mm smooth steel rods (aka [[smooth rod]], aka "drill rod"): Most RepRaps and RepStraps have parts that slide back and forth on 8 mm or nearly equivalent 5/16" smooth rod. A few RepStraps ({{tag|DriveTrains#rotary to linear motion conversion}}) spin a smooth rod with their motor rather than a threaded rod. A few use other sizes such as the 12 mm smooth rod used by [[HaMendel]][http://forums.reprap.org/read.php?152,169733] and BiBone. "O1 drill rod" ? "A2 drill rod" ? | * 8 mm smooth steel rods (aka [[smooth rod]], aka "drill rod"): Most RepRaps and RepStraps have parts that slide back and forth on 8 mm or nearly equivalent 5/16" smooth rod. A few RepStraps ({{tag|DriveTrains#rotary to linear motion conversion}}) spin a smooth rod with their motor rather than a threaded rod. A few use other sizes such as the 12 mm smooth rod used by [[HaMendel]][http://forums.reprap.org/read.php?152,169733] and BiBone. "O1 drill rod" ? "A2 drill rod" ? | ||

* [http://www.inventables.com/technologies/makerslide Makerslide] | |||

* [http://openbuildspartstore.com/ OpenBuilds] | |||

* [http://www.robotdigg.com/product/225/2020-Aluminum-Extrusion-in-Lengths Robot Digg] | |||

* [https://eztube.com EZ Tube] | |||

* [http:// | * [https://alcobrametals.com/products/telescoping-tube/telescoping-aluminum-square-tube/6005a-t6-telescoping-square-tube Telescoping square tube] | ||

* [http://makeblock.cc/ Makeblock] | |||

* | |||

* https://eztube.com | |||

* https://alcobrametals.com/products/telescoping-tube/telescoping-aluminum-square-tube/6005a-t6-telescoping-square-tube | |||

* http://makeblock.cc/ | |||

* The square metal tubes with round holes in the side pictured in [http://blog.reprap.org/2009/02/pull-yourself-together-bot.html "Pull Yourself Together, Bot!"] look a *lot* like grid beam -- would "real" grid beam work just as well? | * The square metal tubes with round holes in the side pictured in [http://blog.reprap.org/2009/02/pull-yourself-together-bot.html "Pull Yourself Together, Bot!"] look a *lot* like grid beam -- would "real" grid beam work just as well? | ||

* http://www.gridbeamers.com/ | * http://www.gridbeamers.com/ | ||

| Line 140: | Line 113: | ||

* http://www.alliedtube.com/sign-support/traffic-sign-posts/telespar-square.asp | * http://www.alliedtube.com/sign-support/traffic-sign-posts/telespar-square.asp | ||

* http://www.mcmaster.com/#steel-structural-tubing/=49tu63 | * http://www.mcmaster.com/#steel-structural-tubing/=49tu63 | ||

* [https://www.makeralot.com/2020-aluminium-extrusion-1-meter-p210/ 2020 T Slotted Aluminium Extrusion] | * [https://www.makeralot.com/2020-aluminium-extrusion-1-meter-p210/ 2020 T Slotted Aluminium Extrusion] | ||

* [https://www.makeralot.com/2020-v-slot-aluminium-extrusion-1-meter-p211/ 2020 V Slotted Aluminium Extrusion] | * [https://www.makeralot.com/2020-v-slot-aluminium-extrusion-1-meter-p211/ 2020 V Slotted Aluminium Extrusion] | ||

| Line 147: | Line 118: | ||

* [https://www.makeralot.com/2060-v-slot-extruded-aluminum-profiles-1-meter-20-x-60-p213/ 2060 V Slotted Aluminium Extrusion] | * [https://www.makeralot.com/2060-v-slot-extruded-aluminum-profiles-1-meter-20-x-60-p213/ 2060 V Slotted Aluminium Extrusion] | ||

* [https://www.makeralot.com/2080-v-slotted-aluminum-1-meter-vslot-20-x-80mm-aluminum-extrusion-p214/ 2080 V Slotted Aluminium Extrusion] | * [https://www.makeralot.com/2080-v-slotted-aluminum-1-meter-vslot-20-x-80mm-aluminum-extrusion-p214/ 2080 V Slotted Aluminium Extrusion] | ||

* [http://web.mit.edu/imoyer/www/portfolio/parametric/ "Parametrically Designed XY Motion Stage"], apparently part of the thesis "Rapid Prototyping of Rapid Prototyping Machines" by Ilan Ellison Moyer. | * [http://web.mit.edu/imoyer/www/portfolio/parametric/ "Parametrically Designed XY Motion Stage"], apparently part of the thesis "Rapid Prototyping of Rapid Prototyping Machines" by Ilan Ellison Moyer. | ||

* [http://builders.reprap.org/2009/08/wrench-built-machine-update.html Wrench-built machine] appears to be built out of grid beam. A RepStrap built mostly out of 1" square perforated tube. ''(Is this a [[Eiffel]] or something else?)'' | * [http://builders.reprap.org/2009/08/wrench-built-machine-update.html Wrench-built machine] appears to be built out of grid beam. A RepStrap built mostly out of 1" square perforated tube. ''(Is this a [[Eiffel]] or something else?)'' | ||

* [http://opensourceecology.org/wiki/LifeTrac_Questions#square_tube_construction_techniques square tube construction techniques]; [http://opensourceecology.org/wiki/gridbeam Grid Beam] | * [http://opensourceecology.org/wiki/LifeTrac_Questions#square_tube_construction_techniques square tube construction techniques]; [http://opensourceecology.org/wiki/gridbeam Grid Beam] | ||

* http://www.gridbeam.com/ | * http://www.gridbeam.com/ | ||

* http://www.gridbeamers.com/ | * http://www.gridbeamers.com/ | ||

| Line 180: | Line 126: | ||

* http://www.alliedtube.com/sign-support/traffic-sign-posts/telespar-square.asp | * http://www.alliedtube.com/sign-support/traffic-sign-posts/telespar-square.asp | ||

* http://www.mcmaster.com/#steel-structural-tubing/=49tu63 | * http://www.mcmaster.com/#steel-structural-tubing/=49tu63 | ||

* [http://bitbeam.org/ Bitbeam] | |||

[http://bitbeam.org/ | |||

* MakerBeam; 80/20 T-slot extrusion; etc. -- [[T-Rep]], [[SamBot]], etc. | * MakerBeam; 80/20 T-slot extrusion; etc. -- [[T-Rep]], [[SamBot]], etc. | ||

* [http://www.openstructures.net/ OpenStructures] | |||

=== water pipe === | === water pipe === | ||

Revision as of 01:33, 22 June 2020

Problem

Most projects require a physical structure. Sizes, shapes, and configurations vary widely.

Approach

Construct projects using a standardized space frame kit optimized for local production.

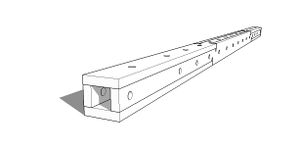

Profile

Replimat frames are constructed using standard lengths of material with a square profile or cross-section. Frame sections may be solid or hollow, constructed from a single piece, laminated, or joined. All Replimat frame sections share the same width, which is 1.5 inches (38.1 millimeters) across each side. Frames of larger or smaller widths may be produced, and work with all of the construction techniques found here. Frames of evenly divisible widths interoperate.

Widths

Frames of larger cross section require fewer holes than frames of smaller cross section that are the same length. Counterintuitively, thicker frame is sometimes faster or less expensive to produce than thinner frame. Thicker frame also creates stronger tri-joints and requires fewer nuts and bolts to create frames of equivalent size and strangth as compared to frame of reduced width. Thinner frame can allow accurate and reproducible model building before final assembly at larger scale. Thinner frame also allows for a finer resolution in the hole pattern, easing complex mounting problems.

Hole Pattern

Holes are centered on each face of the frame and spaced regularly in a repeating pattern at a distance equal to the width of the frame. This geometrical arrangement allows the frame members to reliably produce rigid joints in three dimensions.

Lengths

Frame lengths are intentionally limited to 2, 3, 4, 5, 10, 15, 20, 25, 30, 35, 40, 50, 60, 80, and 100 holes per side. These lengths have been chosen to allow for the creation of all necessary joint configurations (using lengths 2, 3, 4, and 5) as well as to allow for lengths with a center hole and lengths which are evenly divisible by two. The reduced set of lengths allows for improved reuse from project to project, easier identification in photographs and diagrams, and simpler production, handling, and shipping.

Nuts and bolts

Frame sections are joined together using three lengths of bolts, suitable for 1, 2, or 3 stacked frames and share a single size of washers and nuts.

Tools

Frame assembly requires two 13mm wrenches. A socket wrench or battery powered electric socket wrench are highly recommended for quick and easy [dis]assembly.

Joints

Three frame sections can be joined with three nuts and bolts to form a strong three dimensional joint orienting each frame section perpendicular to the others, called a tri-lapping joint or tri-joint. Other joining techniques allow for triangular and hinged joints, which are sufficient to build several useful linkages including the Peaucellier–Lipkin linear motion linkage, Jansen’s linkage, leading link suspension, and more.

Off-pattern holes

-

Offset Frame

Materials

Steel / Aluminum

United states

- Any construction steel supplier.

- 8020 Inc Ready Tube

- McMaster-Carr Bolt-Together Framing

- Allied Tube Telespar and Quick-Punch

- Allied Tube Square-Fit

- S-Square Square Post Perforated

- Ultimate Highway Products Ulti-Mate steel highway sign posts

Canada

- Any construction steel supplier.

- Unistrut

UK

- Any construction steel supplier. (Undrilled)

New Zealand

<sbailard_> VikOlliver, steel and aluminum box section down in NZ, is it metric, or '25.4 mm'? <VikOlliver> Strangley it's in approx 25mm increments...

- sbailard_ is beside himself in surprise.

<VikOlliver> It's sold as 25x50mm box section but you know what they mean...

Wood

Warning

In North America, Template:Tag which is called '1x1' or '2x2' is actually smaller than 1 inch or 2 inches in cross section. This is unfortunate but legal. Speak to a lumber yard or other supplier about getting 'wood which is actually sized 1 inch by 1 inch or 2 inches by 2 inches'. They will be able to help you, possibly by setting up a small order correctly sized material with a local mill, which may be a quick job. (If you are a woodworker, this paragraph is obvious, and we apologize. And you have a table saw.)

A common so-called "two-by-four" (38 mm x 89 mm, 1.5 inch x 3.5 inch) can be ripped and planed into two separate grid beams (each 38 mm square). Does it make any sense to do slightly less work, converting that so-called "2x4 board" into one beam that acts like those 2 grid beams permanently attached to each other, 38 mm x 76 (1.5" x 3.0") with a double row of holes on the 3.0" wide side?

Notes

- Nails - After checking carefully with a nail finder.

- Grit - Use a stiff plastic brush to clean off your wood. Stone pebbles will chip your saw blade.

Similar Construction Systems

- Metric Contraptor adapted to the OpenStructures OSGrid

- MicroRax

- Lynxmotion

- Vex Robotics

- TETRIX Robotics

- Dexion Speedframe

- VSlot,

- fischertechnik aluminum beams,

- 80/20 beams,

- MakerBeam,

- OpenBeam,

- Bosch Rexroth Profiles

- item Aluminum Profiles (the original)

- MK Aluminum Profile System

- pegboard: wood sheets with a regular grid drilled into them

- slatwall (Is this the same as T-slots routed into MDF ?) [1]

- fischertechnik parts -- FTIStrap is the first RepStrap to succeed in printing 3D objects

- the "Servo Erector Set" looks like a quick way to assemble things like a Hexapod Robot CNC Router.

- LEGO -- Category:Lego

- Erector and Meccano -- ?

- Merkur -- ?

- Pitsco TETRIX Parts -- ?

- VEX Robotics Design -- ?

- The Phenostream Robotics BuildPlate construction system looks like a quick way to assemble hand-sized robots -- ?

- The "The 1X2 connector system" -- 1X2, 1X2 Shortcat, and 1X2 Tallcat

- Plastic T-slot

- The Free Universal Construction Kit is a set of adapters for interoperability between several of the above construction "toys").

- 8 mm threaded steel rod (aka "threaded rod" or "allthread" or "M8 studding"): Many RepRaps and RepStraps use all-thread as a easily-adjustable frame material. Many also have at least one axis driven by a "lead screw" of 8 mm threaded road or nearly equivalent 5/16" threaded rod that acts as a worm gear, turned by a stepper motor, that pushes parts back and forth. A few use bigger sizes such as M12 and M10 threated rods in the BiBONE[2] or smaller sizes such as the 1/4 inch threaded rod used in smaller SAE Mendel machines.

- 8 mm smooth steel rods (aka smooth rod, aka "drill rod"): Most RepRaps and RepStraps have parts that slide back and forth on 8 mm or nearly equivalent 5/16" smooth rod. A few RepStraps (Template:Tag) spin a smooth rod with their motor rather than a threaded rod. A few use other sizes such as the 12 mm smooth rod used by HaMendel[3] and BiBone. "O1 drill rod" ? "A2 drill rod" ?

- Makerslide

- OpenBuilds

- Robot Digg

- EZ Tube

- Telescoping square tube

- Makeblock

- The square metal tubes with round holes in the side pictured in "Pull Yourself Together, Bot!" look a *lot* like grid beam -- would "real" grid beam work just as well?

- http://www.gridbeamers.com/

- http://gridbeam.biz/

- http://www.alliedtube.com/sign-support/traffic-sign-posts/telespar-square.asp

- http://www.mcmaster.com/#steel-structural-tubing/=49tu63

- 2020 T Slotted Aluminium Extrusion

- 2020 V Slotted Aluminium Extrusion

- 2040 V Slotted Aluminium Extrusion

- 2060 V Slotted Aluminium Extrusion

- 2080 V Slotted Aluminium Extrusion

- "Parametrically Designed XY Motion Stage", apparently part of the thesis "Rapid Prototyping of Rapid Prototyping Machines" by Ilan Ellison Moyer.

- Wrench-built machine appears to be built out of grid beam. A RepStrap built mostly out of 1" square perforated tube. (Is this a Eiffel or something else?)

- square tube construction techniques; Grid Beam

- http://www.gridbeam.com/

- http://www.gridbeamers.com/

- http://gridbeam.biz/

- http://www.alliedtube.com/sign-support/traffic-sign-posts/telespar-square.asp

- http://www.mcmaster.com/#steel-structural-tubing/=49tu63

- Bitbeam

- MakerBeam; 80/20 T-slot extrusion; etc. -- T-Rep, SamBot, etc.

- OpenStructures

water pipe

- electrical conduit (~20 mm OD steel tube) -- Uconduit

- Steel water pipe and fittings -- Builders/Frank; McWire Cartesian Bot 1 2; Builders/PipeStrap; Development:McWire

- PVC water pipe and fittings -- much lighter weight and lower cost and easier to drill than metal; but is it rigid enough? XtruBot, RepRap Morgan, LISA Simpson, Easy build delta printer, etc.

- possibly using the "PVC pipe construction set" as described at "PVC Pipe Construction Gets Boost with 3D Printed Corner Connectors"

- Large-diameter PVC sewer pipe -- using 6" (or larger) nominal I.D. pipe as a tower/gantry to mount the other parts of the printer. PipeDream

other cut-to-length construction materials

- low-cost softwood dimensional lumber, roughly 18x45mm and 18x70mm (close enough to "1x2" and "1x4"), bolted together -- 1X2 and WolfStrap

- poplar planks -- Tommelise

- extruded aluminum L rails -- Doboz

- #extruded aluminum in other shapes

cut-to-shape construction materials

Should we distinguish between cutting flat materials into a (2D) shape (perhaps with a CNC Router) and perhaps drilling a few holes into the face and edges, vs. cutting large blocks of material into arbitrary 3D shapes?

- cut sheets without any plastic printed parts (RepStrap):

- sheet metal cut, drilled, and folded to approximate the plastic parts of a Mendel -- My Development Page Sheet Metal Mendel

- sheet metal cut, drilled, and folded in other ways -- Tony's sheet metal RepStrap

- "MDF or Ply or Perspex/Acrlic or HDPE or Aluminum" sheets -- Huxley Seedling

- laser-cut plastic (typically clear acrylic) -- Builders/LaserCut RepStraps; PonokoRepRap

- sheet plywood -- PlywoodRepRaps such as LaserCut Mendel; CupCakeStrap; CupCake ??? ; Gunstrap; DeltaTrix ([4]; [5]); etc.

- foamcore -- see imoyer's Foamcore CNC Machine [6] [7] [8]. Can this be laser-cut?

- "flat sheets of wood or plastic (currently HDPE) ... Cut ... on some 2.5D CNC router" -- Isaac, LaserCut Mendel, etc.

- hardwood cut in more or less the exact same shapes as the plastic parts of a Mendel -- Development:Wooden Mendel

- metal cut in more or less the exact same shapes as the plastic parts of a Mendel -- Development:Metal Mendel

- ??? -- Development:McWire Successor ???

- adapting an off-the-shelf milling machine -- Category:MillStrap

- whatever random stuff I had laying around -- Builders/JunkStrap

- Hybrid: cut sheets and plastic printed parts complementing each other:

- Hybrid: Medium Density Fiberboard (MDF) or Acrylic sheet with printed brackets -- Mendel90; Prusa i3#Wood Sheet frame; Prusa i3#Box Style Frame;

- 4 mm aluminum sheet metal and printed brackets -- Orca

- 6 mm aluminum sheet metal and printed brackets -- Prusa i3#Single Sheet Frame

- Dibond: Idea lab one, Mendel90, etc.

To make future generations of self-replicating machines out of such materials seems to require a CNC Router or a Laser Cutter.

other discussions of building material

- Wikibooks: robot building materials implies that cardboard (!) is best for quick prototypes; for functional robots, "wood is probably the best material to start with."; where wood isn't quite durable enough, aluminum is the best metal -- better than steel for most robots.

- Is "edgeboard"[9] the same as corrugated cardboard? It's apparently strong enough to hold up full-sized humans; is it strong enough to hold up an extruder nozzle?

- Is it possible to build a FlatPack RepStrap mostly out of "Laminated Laser-cut Cardboard"[10]?

- Izhar Gafni has made a type of bicycle with a composite frame (cardboard & epoxy?/some polyester?) ("Cardboard Bicycle"). It is apparently waterproof and strong enough to hold up full-sized humans. It is definitely worth an investigation, if nothing else for the other end of the M8 threaded rod there.. are on several levels; Epoxy Granite.

<videoflash type="vimeo">37584656</videoflash>

- User:Mrkim mentions various "Classes of machines",[11][12] including entire classes of machines that the above seems to neglect.

- Carnesmechanical strive to create a collaborative environment to make the purchase of automotive products enjoyable for you. Carnesmechanical is a small blog, is dedicated to bringing unbiased automotive product reviews, car Electronics, auto tool, oil, electrical, welding, accessories.

CAD

Playground

You can try out modifications of the source code right here.