Electrical connectors: Difference between revisions

From

No edit summary |

|||

| Line 13: | Line 13: | ||

=Approaches= | =Approaches= | ||

[[File:Wago5T.jpg|thumb]] | [[File:Wago5T.jpg|thumb]] | ||

Wherever possible, replimat projects are wired with versatile and fully reusable [https://www.wago.com/us/wire-splicing-connectors/compact-splicing-connector/p/221-615 221-615 five position Wago lever nuts] or equivalent terminal blocks (link?). These accept larger 20 - 10 gage wire than the more commonly used 221-415 connectors' 24 - 12 gage range. | Wherever possible, replimat projects are wired with versatile and fully reusable [https://www.wago.com/us/wire-splicing-connectors/compact-splicing-connector/p/221-615 221-615 five position Wago lever nuts] or equivalent terminal blocks (link?). These accept larger 20 - 10 gage wire than the more commonly used 221-415 connectors' 24 - 12 gage range. | ||

Revision as of 06:04, 28 March 2021

Introduction

Nearly every project requires many electrical connections.

Challenges

There are too many different shapes, sizes, and varieties of electrical connectors, switches, plugs, and receptacles to count. Additionally, each often requires it's own special tools, processes, consumables, etc.

Approaches

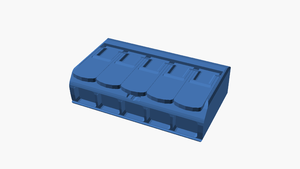

Wherever possible, replimat projects are wired with versatile and fully reusable 221-615 five position Wago lever nuts or equivalent terminal blocks (link?). These accept larger 20 - 10 gage wire than the more commonly used 221-415 connectors' 24 - 12 gage range.

The Wago 221-615 Holder/Mount allows for Wago 221-615 connectors to be panel mounted and easily reconfigurable bus bars.

Development targets

Adjust the Wago 221-615 Holder/Mount to fit the Replimat grid.