|

|

| Line 1: |

Line 1: |

| {{Parts infobox | | {{Parts infobox |

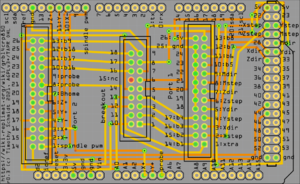

| |image = Bolt-thumb.png | | |image = Grbl4crp850r0.3.png |

| |designers = [[User:Tim|Timothy Schmidt]] | | |designers = [[User:Tim|Timothy Schmidt]] |

| |date = 2019 | | |date = 2021 |

| |vitamins = | | |vitamins = |

| |materials = | | |materials = |

| |transformations = | | |transformations = [[Soldering]], [[Etching]] |

| |lifecycles = | | |lifecycles = |

| |tools = [[Metal lathes]] | | |tools = [[Soldering irons]] |

| |parts = | | |parts = [[Printed circuit boards]], [[Solder]], [[Headers]] |

| |techniques = | | |techniques = |

| |stl = | | |stl = |

| Line 18: |

Line 18: |

|

| |

|

| =Introduction= | | =Introduction= |

| Fastening two or more parts together sometimes requires special tools, electricity or compressed air, sometimes damages the parts themselves, and sometimes cannot be undone.

| |

|

| |

| Fastening two or more parts together should be quick, easy, produce a strong joint, and be a fully reversible process.

| |

|

| |

|

| =Challenges= | | =Challenges= |

| Bolts of different lengths are required to join one, two, and three thicknesses of [[frames]] to brackets, panels, and each other.

| |

|

| |

| The combination of weld nuts and furniture bolts suggested in [https://www.ocf.berkeley.edu/~mwilliams/reading/construction/How-to-Build-With-Grid-Beam.pdf How to Build With Gridbeam] loosens rapidly and structures built with them begin to wobble quite quickly. A drop of loctite on each nut's threads would help.

| |

|

| |

| <youtube>tkEVwpl2S4Q</youtube>

| |

|

| |

|

| =Approaches= | | =Approaches= |

| A selection of nuts and bolts have been chosen to interoperate with various [[frames]] and are listed in the Parts section.

| |

|

| |

| Replimat is currently using hex head bolts and nylock nuts to address the loosening issue.

| |

|

| |

| =Parts=

| |

| ==8mm frame==

| |

| M3xXX, M3xYY, M3xZZ bolts

| |

| ==38.1mm frame==

| |

| <gallery>

| |

| Bolt-m8x50.png|M8x50

| |

| Bolt-thumb.png|M8x90

| |

| Bolt-M8x130.png|M8x130

| |

| </gallery>

| |

|

| |

| ==40mm frame==

| |

| M12x50, M12x90, M12x130

| |

| ==100mm frame==

| |

| M25xXX, M25xYY, M25xZZ bolts

| |

|

| |

| =Life cycle=

| |

| ==Degenerative transformation==

| |

| Long bolts can be cut to form shorter bolts.

| |

| ==Last use==

| |

| Stripped, bent, or abraded bolts degrade to abrasive pellets for [[ball mills]].

| |

|

| |

| =Suppliers=

| |

| * [https://shop.stafast.com/ Stafast]

| |

|

| |

|

| =References= | | =References= |

| * [https://en.wikipedia.org/wiki/ISO_metric_screw_thread Wikipedia: ISO metric screw thread]

| |

| * [https://www.thingiverse.com/thing:193647 NUT JOB | Nut, Bolt, Washer and Threaded Rod Factory]

| |

| * [https://www.thingiverse.com/thing:4635654 Metric screw measuring device - M2/2.5/3/4/5 4-50mm]

| |

| * [https://www.thingiverse.com/thing:4792033 Metric Screws Quick Measure jig M6 - M14]

| |

| * [https://eurocodeapplied.com/design/en1993/bolt-design-properties Table of design properties for metric hexagonal bolts M5 to M39 (stress area, shear strength, tensile strength, bearing strength)]

| |

| * [http://www.metrication.com/engineering/fastener.html Metrication.com: Metric Fasteners]

| |