Caster joints: Difference between revisions

From

No edit summary |

No edit summary |

||

| Line 9: | Line 9: | ||

=Introduction= | =Introduction= | ||

Casters are one of the most widely used [[parts]] and come in many shapes and sizes, often with a 4-hole mounting plate. | |||

=Challenges= | =Challenges= | ||

Mounting the caster securely through all four mounting holes near a tri-joint (which tend to be at the corners of projects, exactly where casters want to be) isn't easily accomplished. | |||

=Approaches= | =Approaches= | ||

| Line 17: | Line 19: | ||

Caster-joint-suboptimal.scad.png|link=[[Caster joints]]|Suboptimal caster joint | Caster-joint-suboptimal.scad.png|link=[[Caster joints]]|Suboptimal caster joint | ||

</gallery> | </gallery> | ||

One corner configuration secures the caster at two points and centers the vertical frame member on the caster. The other applies significant force, with the possibility of a bending moment on the caster mounting plate. | |||

=References= | =References= | ||

Revision as of 01:22, 3 April 2021

Technique: Caster joints

| Tools: | Wrenches |

|---|---|

| Parts: | Frames, Bolts, Nuts, End caps, Casters |

| Techniques: | Bolting, Tri joints, Shelf joints |

Introduction

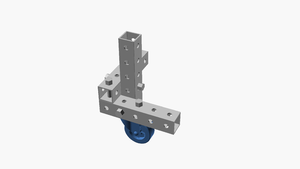

Casters are one of the most widely used parts and come in many shapes and sizes, often with a 4-hole mounting plate.

Challenges

Mounting the caster securely through all four mounting holes near a tri-joint (which tend to be at the corners of projects, exactly where casters want to be) isn't easily accomplished.

Approaches

-

Suboptimal caster joint

One corner configuration secures the caster at two points and centers the vertical frame member on the caster. The other applies significant force, with the possibility of a bending moment on the caster mounting plate.